Materials

As laser experts we can help you find the material you need.

Many different materials up to a size of 813mm x 505mm can be laser cut and engraved. With the CO2-Laser most materials can be cut and engraved. A fiber laser allows to permanently mark metals and some plastics.

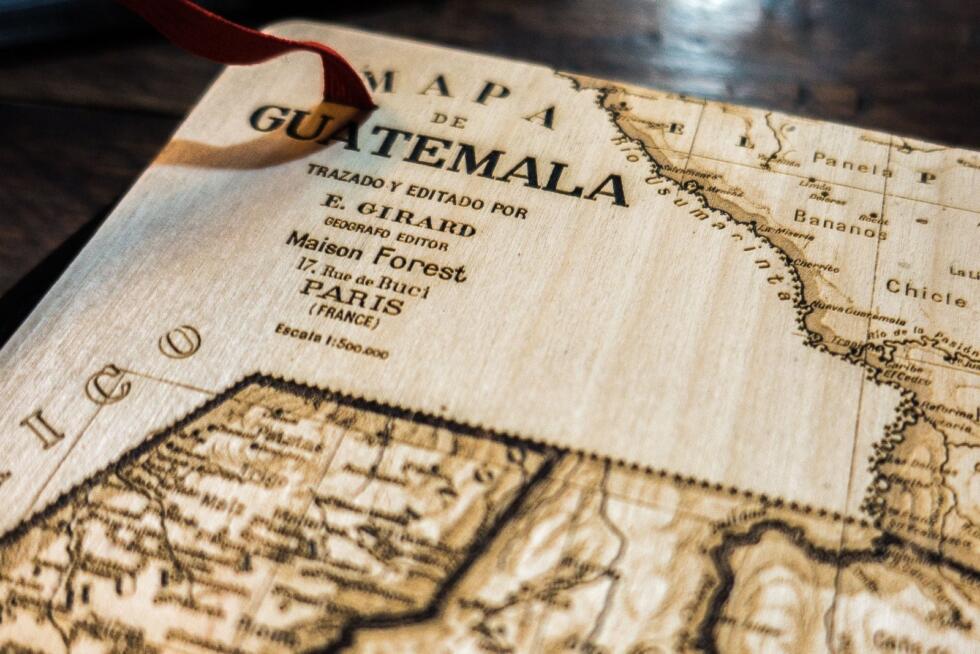

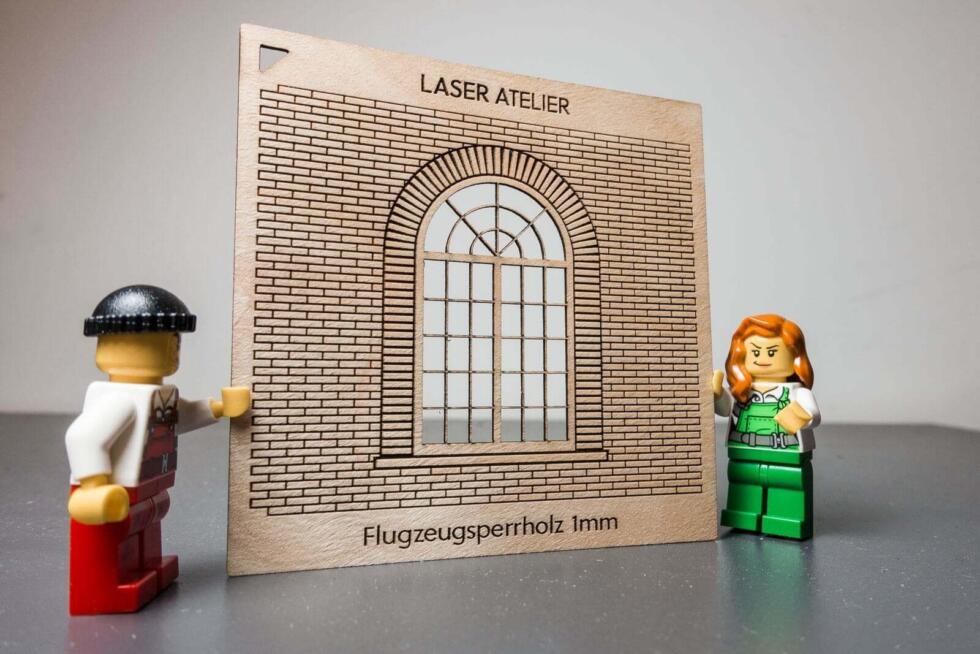

Wood

Wood and plywood are the easiest materials to laser engrave and very popular. Precise cuts and deep engravings with good contrast are possible in most woods.

Possibilities with wood and plywood

Wood is a versatile material for laser processing. All types can be engraved. The resulting look depends on the type and the used laser settings. Cutting is possible with plywoods and thinner solid wood and veneers.

Laser cutting and engraving has many different applications. Popular are branding and personalization of objects. Depending on the laser parameter many different looks can be achieved: From very detailed engraving of small details to a more traditional branding-iron look.

Applications:

- Gifts for clients and personalized marketing material.

- Personalisation and branding of products.

- Model building for prototypes and architecture models.

- Signage, labels and plates

- Point of sale (POS) for companies

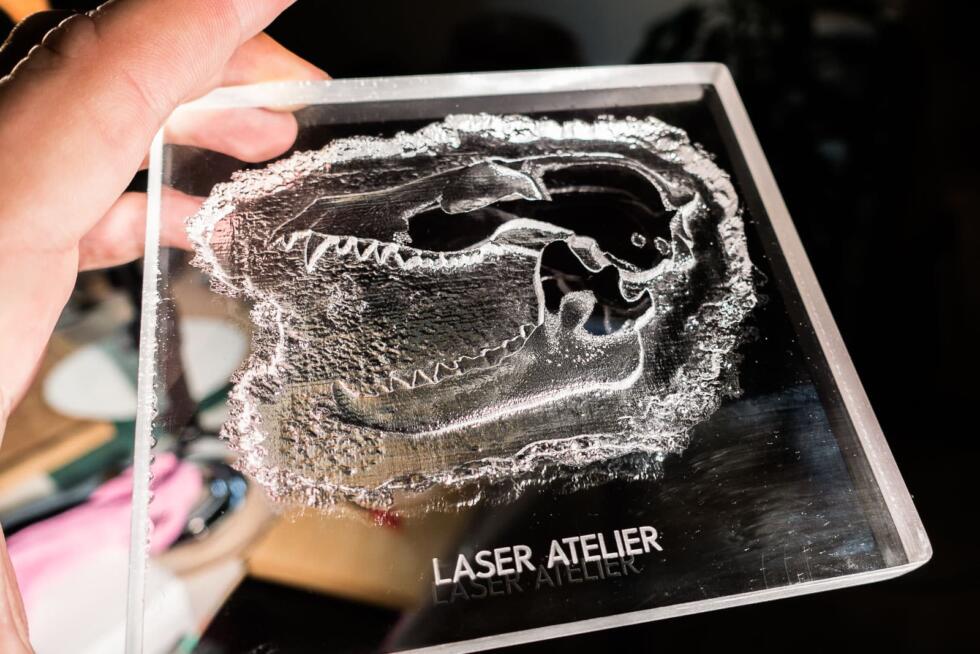

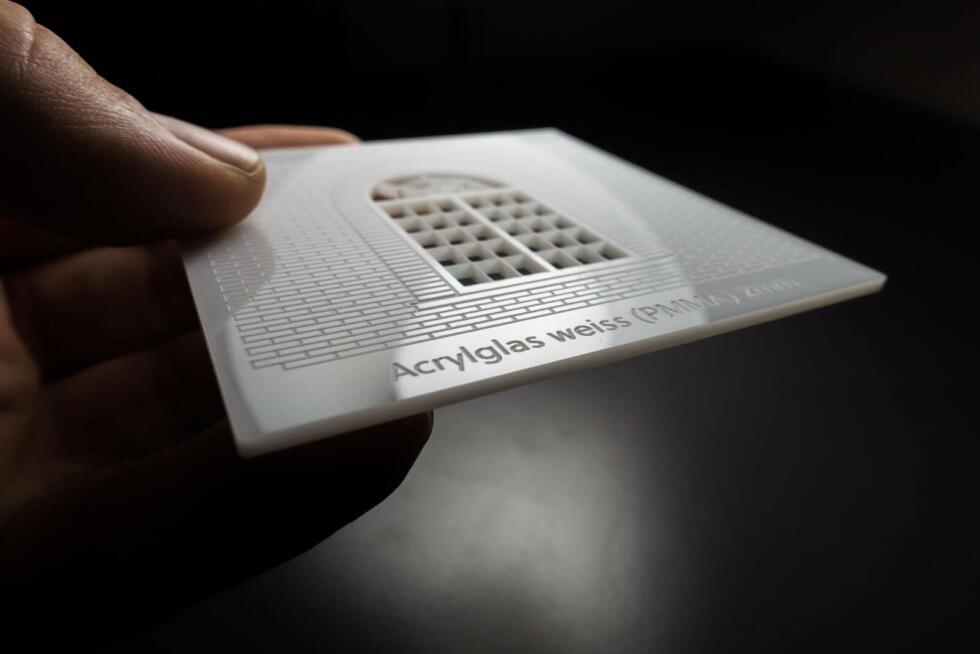

Plastic

Plastic like acrylic, POM and many others can be laser cut an engraved. Precise cuts and detailed engravings are possible.

Possibilities with plastics

Many different plastics can be laser cut and engraved with a laser. From cutting and engraving of acrylic to marking specialised plastics like POM.

Possible applications:

- Plastic parts of products

- Engraving and marking of parts and machines.

- Marking of buttons and switches

- Packaging and personalisation of products.

- Signage and signs.

Laser processes

Cutting and engraving of plastic

Many plastics can be cut and engraved by laser. By laser engraving parts of the surface the material can be precisely removed. Engraving of very small details like text or graphics is possible. Most types of plastic can be engraved. Cutting is limited to certain types and thicknesses.

Coloring of plastics

Plastics can be colored by precisely heating the material in a very small spot. This process can make some types of plastic darker and some lighter. The resulting marking is depending on the type and composition of the plastic material.

Foaming of plastics

A fiber laser can mark some plastics white. This happens by melting the material to create small gas bubbles. This thin foam layer can reflect light in a different way and appear brighter than the rest of the material.

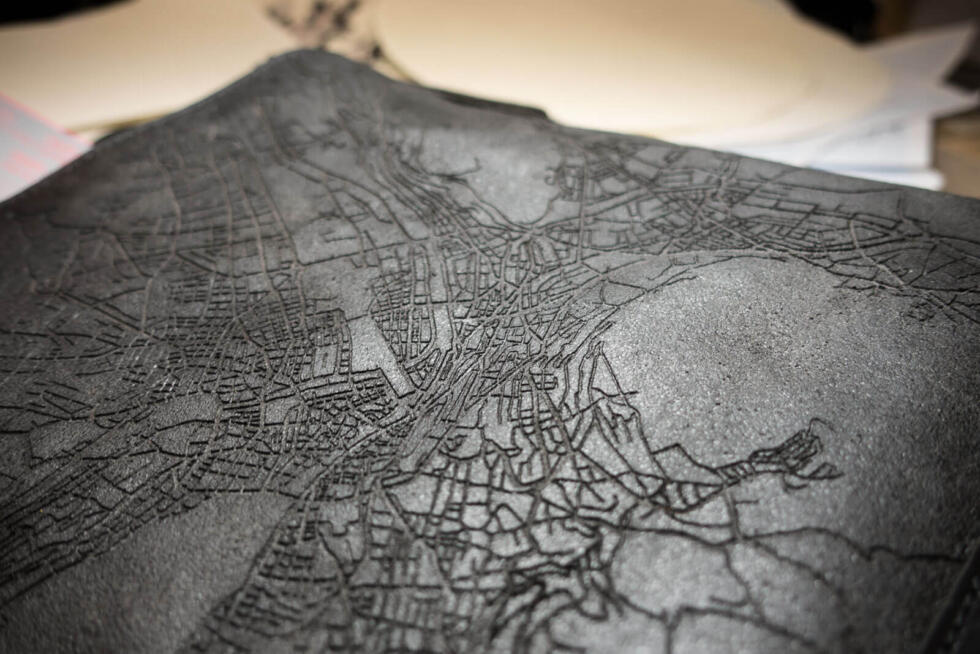

Textile

Many types of textile and also leather can be cut and engraved with precision and speed. Possible materials range from synthetics to natural textiles.

Possibilities with textile and fabric

Textile have many different applications. It is possible to laser cut intricate patterns in textile materials and leather. Even small holes for sewing are not a problem. Engravings are possible on some materials.

Synthetic textiles like Nylon and Polyester are very well suited for laser processing. The cutting edges get sealed by heat of the laser and do not require further processing.

Possible use cases:

- Cutting of textile products and patterns

- Engraving on denim, softshell, fleece and more is possible for branding and personalisation.

- Industrial products, prototypes and research use various textiles.

- Marketing materials made from texil

- Leather products

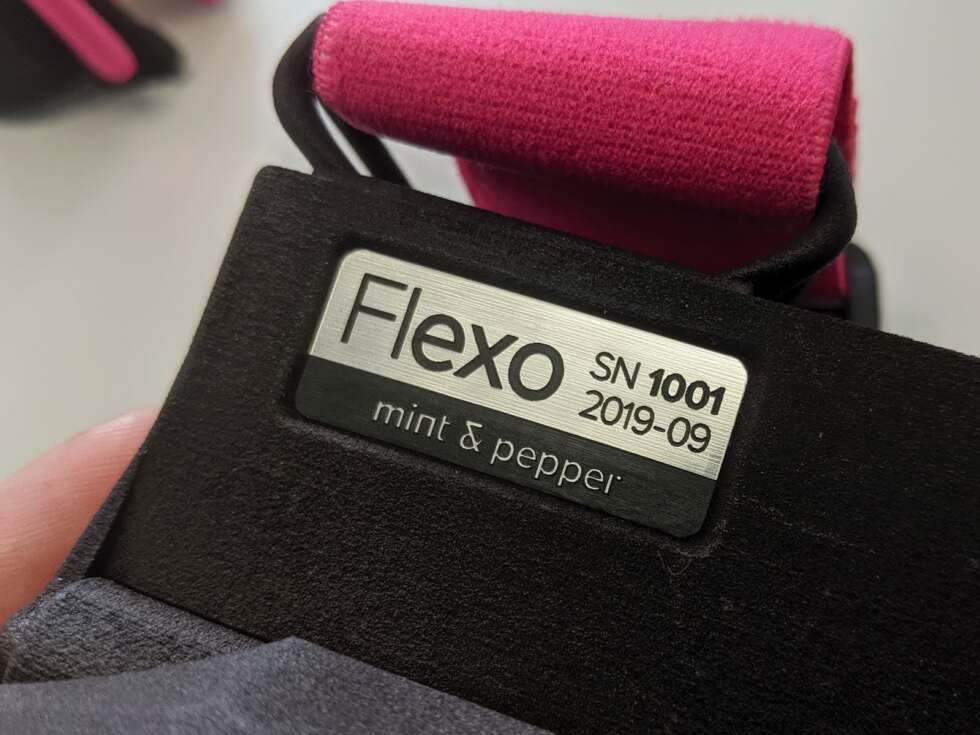

Foil

Many plastic and some metal foil can be cut and engraved with great speed and precision with a laser cutter. Possible use cases are stencils for spray painting, detailed labels or industry uses.

Possibilities with foil

Many foils can be cut with speed and precision. On some materials a high-detail engraving is possible. A popular use case is the production of stencils for spray painting or high-contrast engraved tags and nameplates.

Not all kinds of foil can be laser processed. Any material containing PVC must not be laser cut.

Possible uses:

- Engraving of laser foil for labels and name tags.

- Cutting of double-sided tape for industrial uses.

- Fashion design

- Stencils for spray painting

- Decoration and design.

- Research and industry uses

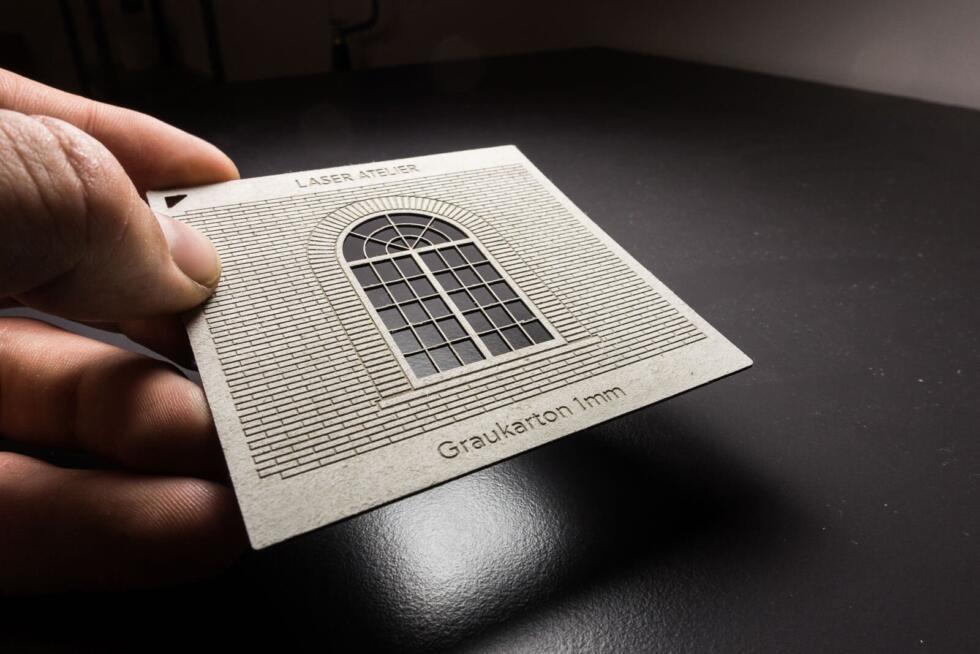

Paper and cardboard

Many paper and cardboard materials can be cut and engraved with high speed and precision. Common applications are architecture, branding and prototyping.

Possibilities with paper and cardboard

Paper and cardboard have many different uses and are well suited for laser processing. Common uses are gifts for clients, packaging or architecture models. Even thicker cardboard can be cut but marks form laser cutting will be visible.

Possible applications:

- Packaging

- POS und client gifts

- Marketing materials

- Cards and tags

- Architecture models and model making

Glass and Ceramic

Many glass types and some ceramics can be laser processed. Permanent and durable markings are possible.

Possibilities with glass and ceramic

Many types of material can be laser marked permanently and with good contrast. The process is contactless and doesn’t need a special pre-process. Glass is often used in laboratory and research settings. Ceramic has a lot of industrial uses.

Engraving by laser etches the surface slightly and turns the marking white and matte.

Possible applications:

- Permanent marking of cuvettes and beakers for laboratory use.

- Engraving of mirrors

- Decoration for branding and marketing

- Other laboratory, research and industry uses